In competitive racing, a car is a finely-tuned symphony of interdependent systems that work together to make a complete weapon. And as such, improvements in one area often require sacrifices in another. So today, we delve into a crucial aspect of this intricate dance: weight reduction. While it’s common practice to shed pounds for speed & agility, it might surprise you that there are some downsides. So put that cutting wheel down for a second, and don’t rip that AC out just yet. Let me talk to you about what I did to my E90 in preparation for GRidlife’s Club TR class.

Why less weight…

With all things equal, the lower your power-to-weight ratio, the faster your car will be. 1) A lighter car accelerates more easily. As cliche as that sounds, a vehicle that accelerates quickly can be the difference between winning and losing. 2) Lighter cars are also generally more agile and responsive. They can change direction quickly, making it easier to maneuver through corners. 3) Lighter cars require shorter braking distances, because there is less momentum to slow down. This improves the car’s ability to decelerate quickly. 4) It also aids in less stress on tires & brakes, reducing wear & fatigue. Ask a C6 Corvette owner about their consumables (brakes/tires) cost. Stopping, turning, and accelerating a 3100lb car will cost you far more in consumables than something like a Lotus Exige at 2500lbs, even though they have similar power-to-weight ratios.

But even though I listed all these benefits, don’t go outside cutting everything off your damn car. “Karts” are stupid, due to the drag they cause and the loss of some structural integrity. It’s essential to have a light vehicle and keep your chassis as stiff as possible (for a racing application). That’s why it’s best to replace heavy components with alloys, titanium, carbon, and fiberglass to save weight.

Downsides to having a light car??

Blasphemy, I know. But there are a few downsides to having a car that is too light. 1) They are typically more fragile. Lightweight components tend to crack or crash more easily. An example would be a car door made out of FRP/Carbon, which absorbs far less impact than the one made out of steel (like on most passenger cars). 2) Extreme lightweight vehicles can be more susceptible to instability at high speeds due to reduced downforce. Fun fact: The more your car weighs, the more traction it has. Have you ever wondered why we use lbs when discussing downforce numbers? Essentially, you add that much weight to the car, increasing traction. Lastly, but likely the most crucial real-word barrier, is cost. Building a race car is costly, and lighter high-end components can get expensive fast. Look up a ‘dry carbon’ anything, and your eye may shed a tear.

What can we do with this E90 in Club TR?

Falken Club TR with Gridlife has a minimum weight of 2,500 lbs for cars with engines under 2.5 liters (if naturally aspirated) or 1.6 liters (if forced induction). However, for vehicles with special exemptions and a car with another engine swapped in under 2.5 liters, the minimum weight is 2550 lbs. The E90 falls under that special exemption due to a non-M engine under 3.0 liters, so I must get to 2550 lbs. But I’ll tell you right now: There’s no f****** way that’s going to happen. Club TR does not allow you to gut a car completely like the good lord intended. I can’t hack away on the chassis because it has to remain in stock with “no fabricated components.”

The doors must also remain stock, and I have 4 of them, so that’s not ideal. Speaking of 4, each of those doors must keep the OEM glass as well, which polycarbonate (Lexan) would have really helped cut down some weight. I also have to retain “OEM interior components”, but they can be trimmed or modified to accommodate safety items like seats and rollbars. However, most people in the class remove most things inside when a cage or rollbar is added. I notice that all dashes & door cards are intact, so I will follow that lead. I am also allowed bolt-on components (like a hood and trunk) to be made from another material. Can someone make me one out of dry carbon or something? This is going to be hard without it.

So where do I start?

For this article, I wanted to start with the things that won’t cost me anything... or not much. Naturally, I started ripping out the interior. It’s legal because I wrote my intentions here. You all see it. You are my witnesses. I’ll be reusing a seat & steering wheel I had in my last two track cars (the Cayman and Corvette). And I’ll be adding another racing seat to scare the shit out of the misses during testing. This should save a big chunk compared to the OEM BMW Sport seats & steering wheel. I also removed all the components from the trunk. The BMW E9x series has a plastic panel that holds the spare tire & emergency stuff. I’ll need to cover this hole in the future, as I don’t want debris flying in or exhaust fumes coming up. I’ll also shed some weight with the backseats & airbags being yeeted to the curb. The previous owner did me a solid with getting rid of the factory resonators and mufflers already. He also sold me a vehicle that leaks most of its fluids, so the old girl is also losing its water weight in a sense. The most significant weight decrease may come from me not being so fluffy. Yeah I’m going on my own race car diet, as people often forget that if they made themselves jockey-size, their car would also lose weight.

Slightly Worried…

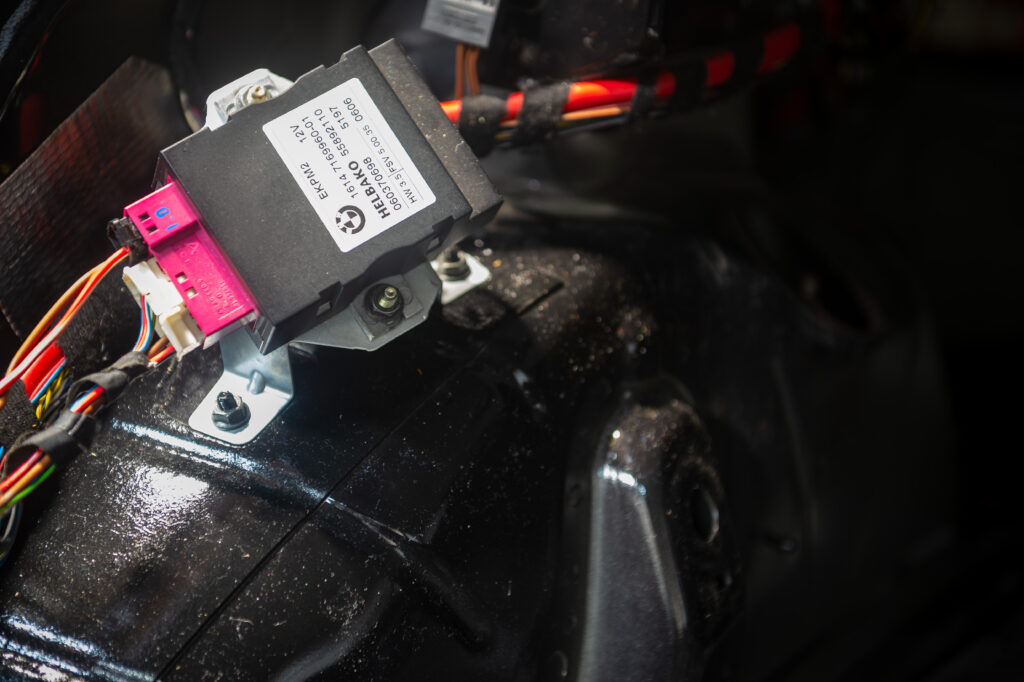

I must admit, I’m slightly worried about taking too many things out. The BMW electrical system is a Controller Area Network (CAN) bus system. CAN is excellent for modern cars, for a few reasons. 1) It allows you to transfer incredible high-speed data at 500kb per second. 2) A CAN system also enables you to have a lot of subsystems that can control actuators like power windows, and features like parking assist (and everything else spirited drivers usually TURN OFF in their car as soon as they step in it). These systems also give you real-time alerts and run system checks independently. For example, your safety restraint system (SRS) runs a review every time you turn your key on. 3) CAN Bus is also the most common communication protocol in your OBD2 port. This is one of the reasons why aftermarket gauges & gauge clusters use OBD2 ports to receive critical powertrain data for your car.

That can be great, or a nightmare…

In my work machine, there are 21 digital modules. To keep things simple, module 11 loses power, and it’s tied to modules 12-15. Typically, this is used for safety. A critical malfunction would happen if 11 controlled something that 12-15 relied on without it. Chaining CAN modules can provide a backup system or a fail-safe mechanism if one module or communication channel fails. And, chaining modules makes diagnosing and troubleshooting problems in the vehicle’s systems easier. If an issue arises in a particular subsystem, it can often be isolated more quickly and efficiently, reducing repair downtime. Chaining CAN modules can also have cost benefits. Instead of designing a single, monolithic ECU that handles all functions, automakers can use off-the-shelf modules and adapt them for specific purposes, reducing development and manufacturing costs.

But with all that said, I want to ensure that I don’t eliminate something that will leave the car stranded… or acting insane. I don’t want to be on the wrong end of discovering if the BMW myths about electronics are true. So I will have to look more into the schematics and what I can code out.

Braking Later…

In the meantime, I will focus some attention on the brakes. At 3,300lbs, this E90 BMW sure has small brakes for such a heavy car. To BMW’s credit, they didn’t expect their entry-level luxury car to be used as a sports car, let alone a track car. So, in the next episode of I LIKE PAIN, I will review the brake upgrade I recently did, which equipped me with even bigger rotors than I have in the front of my high-horsepower S2000.

CALL TO ACTION…

We do need a favor from you. In this 30-second video age, it’s tough for us writers to stay ahead of the game. We need readers like you to share these stories on your socials or drop us a like or comment. We love talking to you all, and it helps the algorithm overlords stay happy. As always, I appreciate you reading this, and see you next time.

Strip it and PDM it!

Only problem is I would like the engine stuff to be controlled by a ECU thats not OEM or Motec so trying to figure out what can control the valvetronics.

The E90 chassis without the fat suit should feel great.

kamagra en ligne: kamagra oral jelly – kamagra pas cher