Who is Steer Smarts?

Steer Smarts makes steering solutions for Jeeps. Major solutions. Overkill solutions… if there was such a thing… which there’s not.

In a nutshell, Steer Smarts uses Ford F650-grade steering components on Jeeps. The ends are forged & use 30mm ball studs.

The Steer Smarts parts we installed…

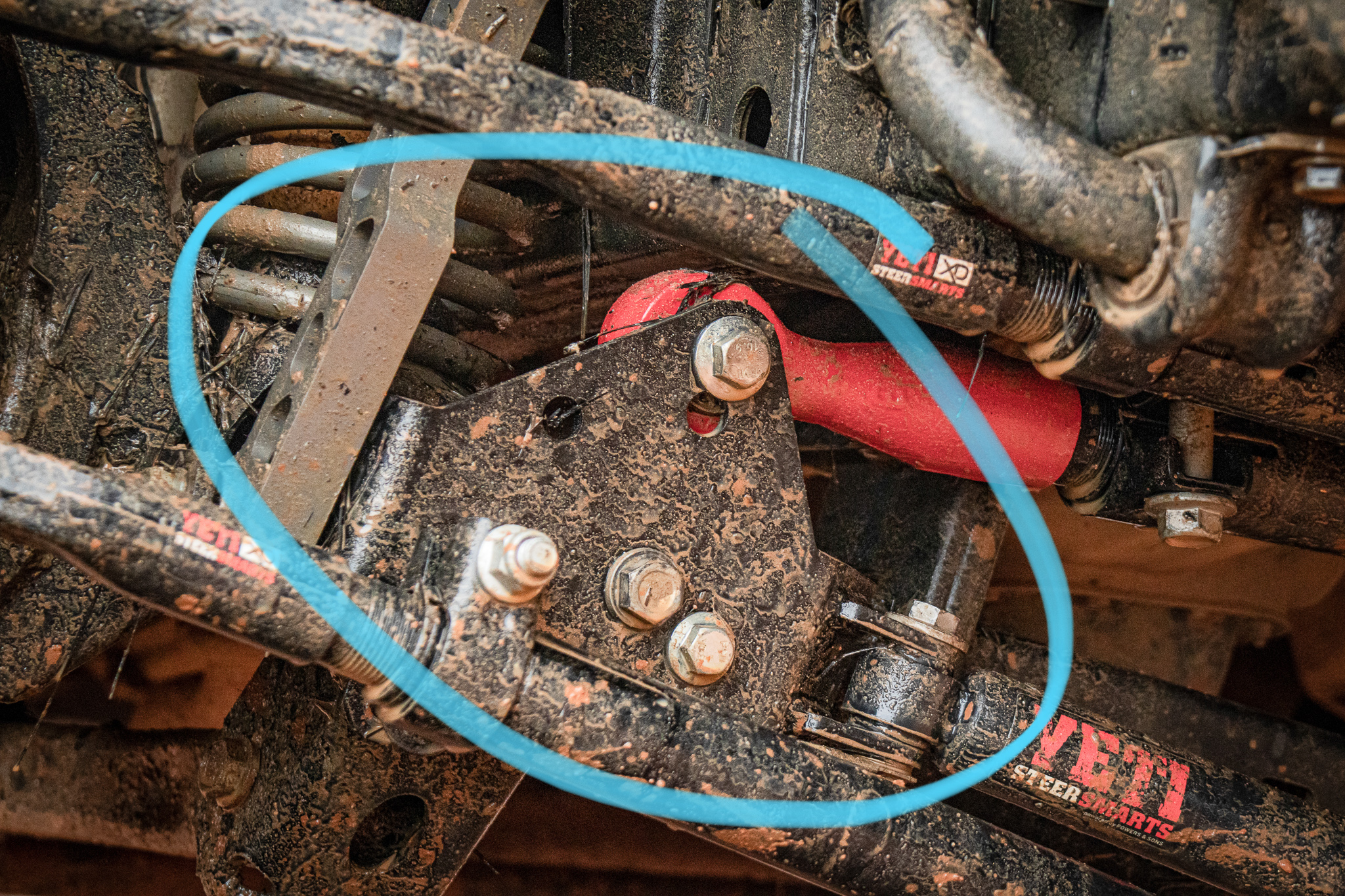

1) Yeti XD Track Bar – keeps the axle centered left-to-right under the Jeep.

2) Yeti XD Track Bar Relocation Bracket – corrects the angles of the steering with a lift & larger tires.

3) Yeti XD ‘No-Drill’ Top Mount Draglink – turns the tires left/right, and straightens/aligns the steering wheel. No need to drill-out your stock knuckle with this Draglink!

4) Yeti XD Tie Rod Assembly – keep the tires straight. These take on a lot of stress & rebound with bigger tires.

5) HD-N Steer Stabilizer – is the shock; it slows down the rebound of the steering, absorbing violence in the steering wheel.

6) Yeti XD Damper Bracket – securely mounts & reenforces the HD-N steer stabilizer.

7) Yeti XD 2.5-3.5” End Links – attach the swaybar to the axle. Improves steering response & keeps the Jeep stable in turns (for 2.5-to-3.5-inches of lift).

The Tie Rod Ends are all forged steel, and were designed & based off the F650 – so they are technically a 2.5-ton end. They have 30mm ball studs instead of 26mm (stock). The joints all use steel-on-steel ball bearings rather than plastic bushings. The ends all have zerk fittings to maintain the joints. Joints also have Steer Smarts’ reverse-pin technology, also known as ‘no-flop’. Internally there is a stud on the back of the ball, and then Steer Smarts machines a channel in the joint to only allow articulation in the direction that you want.

Adjuster tubes are 1-5/8” OD chromoly with ¼” wall thickness. Steer Smarts uses clamps instead of jam nuts.

End links are aluminum extrusions.

Steer Smarts offers the tie rod adjuster tube in a 1-3/4” aluminum tube with all-new aluminum clamps, and this is a direct replacement for the chromoly tube.

The Track Bar relocation bracket also relocates our stabilizer up higher, or gives you a mounting location for hydro assist.

Parts are all e-coated, and some are powder coated on top of that for maximum corrosion resistance.

Why you need this…

Why you need this…

Wranglers have a straight/solid front axle. It’s part of why they’re the most capable 4×4 you can buy. But it’s also an old school design, and it doesn’t provide the best handling characteristics. Add bigger tires to your Jeep, and you wear out the steering components on that straight axle… fairly quickly actually.

My Jeep had less than 30,000 miles on it, and the wear-rate on my steering components (on 37s) was significant. But it’s a gradual breakdown, not an all-the-sudden ‘break’… making it hard to realize sometimes. My Jeep’s factory steering components had deteriorated to the point where it would wander around in its lane, and I’d experience a slight intermittent back-&-forth pulsing in the steering wheel… usually at low speeds, like when you turn at a 4-way stop.

How it feels…

How it feels…

It basically feels like a new Jeep! Like you just rolled all the miles off the clock! There is a HUGE difference in driving feel & overall road manners. And there’s an immediate reward & satisfaction for dollar spent. You feel much more confidence, and much less sketchiness running down the road. The Jeep doesn’t wander on the highway. Steering response is more direct & immediate. And – the Jeep stays MUCH more level on turn-ins. It makes the Jeep safer, lets you relax your grip on the steering wheel, and 110% makes the driving experience more enjoyable… like it should be.

You should absolutely budget for this when you add a lift & bigger tires to your Jeep. The good news is, it does NOT necessarily have to be done immediately, so you have some time to budget. But when you do it… trust me… you’ll wish you’d done it sooner.

*Shout-out to BLACK BEAR OFF-ROAD for the recommendations & install

Kamagra Commander maintenant: Achetez vos kamagra medicaments – Kamagra Oral Jelly pas cher